JX series CNC Angles Automatic Punching , Marking , Shearing Production Line

The CNC angle steel punching production line is used for punching, marking, and shearing processing of angle steel. It is widely used in the production of angle steel towers in the power transmission and communication industries, and can also be used for angle steel components in the construction industry, railway, and bridge engineering. As it can jointly complete several functions such as marking, punching, and shearing, it can also be called the joint production line of CNC angle steel.

Punching

Marking

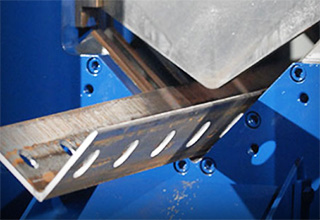

Shearing

Angle steel-Electric power tower

★The CNC angle steel punching production line is used for punching, marking, and shearing processing of angle steel. It is widely used in the production of angle steel towers in the power transmission and communication industries, and can also be used for angle steel components in the construction industry, railway, and bridge engineering. As it can jointly complete several functions such as marking, punching, and shearing, it can also be called the joint production line of CNC angle steel.

★This production line comprises a transverse material table, a flipping feeding device, a feeding channel, a CNC trolley, a punching machine, a shearing unit, a conveying rack, and a sorting channel, equipped with hydraulic, pneumatic, and electrical control systems.

★The equipment possesses an independent hydraulic power system and an electrical CNC system, controlled centrally.

★The tooling is easy to install and accurately positioned, which greatly reduces work stoppage and tooling adjustment time, enhancing work efficiency and expanding the equipment’s application range.

★The JX series equipment has one typing station, two punching stations, and one shearing station, enabling multi-variety and multi-diameter typing, punching, and shearing.

| Model | JX0808 | JX1010 | JX1412 | JX2020 | JX2020S | Unit |

| Range of processed angles | 40×40×3—

80×80×8 |

40×40×3—

100×100×10 |

40×40×3—

140×140×12 |

63×63×4—

200×200×20 |

63×63×4—

200×200×20 |

mm |

| Maximum punching diameter | Φ25.5 | Φ25.5 | Φ25.5 | Φ25.5 | Φ25.5 | mm |

| Maximum punching force | 400 | 400 | 600 | 1000 | 1000 | kN |

| Maximum imprinting force | 600 | 600 | 600/1000 | 600/1000 | 1000 | kN |

| Cutting force | 900

Single-edge cutting |

900

Single-edge cutting |

900

Double-edged cutting 1800 Single-edge cutting |

1400

Double-edged cutting |

1400

Double-edged cutting |

kN |

| Maximum feed side material length | 12 | 12 | 12 | 12 | 14 | m |

| Electrical system | Yokogawa PLC | |||||