DJ series CNC corner band sawing machine

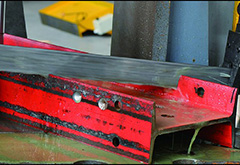

The high-speed CNC corner band sawing machine is mainly used for sawing H-beams, channel steel, angle steel, and other materials in the construction, bridge, tower, and lattice industries.

Sawing

H beam—Steel Structure

★The high-speed CNC corner band sawing machine is mainly used for sawing H-beams, channel steel, angle steel, and other materials in the construction, bridge, tower, and lattice industries.

★The sawing machine adopts a double column linear guide rail structure, which has good rigidity and stability. The sawing section is flat, and the sawing feed is controlled by hydraulic cylinder, with hydraulic valve stepless speed regulation.

★The machine has a rotating function of ±45°, which can complete any angle cutting between -45° to 45°. The angle is locked by a hydraulic cylinder to prevent angle deviation during sawing. The angle signal is collected by a magnetic scale to ensure positioning accuracy.

★The main drive adopts a high-power reducer with strong power and reliable performance, which has been precisely balanced and calibrated for stable and reliable operation.

★The saw bow is equipped with an upper clamping device, which can still clamp the workpiece tightly even after rotating the angle, preventing the lower end of the workpiece from being unclamped when clamping from one side.

★This equipment can be combined with our SWZ beam drilling line and locking production line to form a flexible production line for steel structure secondary CNC processing equipment.

| Model | DJ400A | DJ700A | DJ1000A | DJ1250A | Unit |

| Maximum workpiece(90°) | 400×400 | 700×400 | 1000×500 | 1250×600 | mm |

| Maximum workpiece(45°) | 280×400 | 480×400 | 700×500 | 880×600 | mm |

| Minimum workpiece | 150×80 | 150×80 | 150×80 | 150×80 | mm |

| Corner range (standard) | ±45° | ±45° | ±45° | ±45° | |

| Saw strip specifications | 5200×41×1.5 | 6420×41×1.3 | 8800×67×1.6 | 9800×67×1.6 | mm |

| Saw strip linear speed | 5—200 | 5—200 | 5—200 | 5—200 | m/min |

| Spindle motor power | 4 | 7.5 | 11 | 15 | kW |

| Electrical system | Mitsubishi PLC | ||||