SZ series horizontal CNC deep hole drilling machine

SZ series horizontal double-spindle CNC deep hole drilling machine adopts gun drill and BTA drill to complete deep hole drilling,and the drilling surface roughness is Ra3.2 ~ Ra1.6.

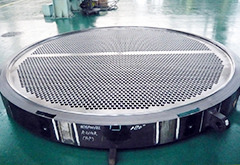

It is mainly used for deep hole drilling of large thick tube sheet in various heat exchangers, pressure vessels, petroleum, chemical, nuclear and other fields.

Deep hole processing

Tube sheet-Heat Exchanger

★The horizontal deep hole drilling machines are mainly used for processing holes on tube and shell heat exchangers used in industries such as petroleum, chemical, pharmaceutical, thermal power plants, and nuclear power plants.

★This machine has high efficiency and good accuracy, with a roughness of Ra3.2 on the drilled surface, hole diameter accuracy of IT9-IT10, and straightness of 0.1mm/100mm.

★The equipment can use either an external chip removal gun drill or an internal chip removal single tube BTA drill.

★It has two spindles that can work separately or simultaneously (with adjustable spacing).

★Specially designed guide sleeve structure that can be directly pressed onto the workpiece, providing secondary guidance for drilling tools to improve machining accuracy.

★The three CNC axes of the machine are equipped with grating rulers to monitor whether the positioning and feeding are completed accurately and feedback to the system, forming a closed-loop control to ensure machining accuracy.

★The workpiece clamping bend plate is divided into two pieces with adjustable spacing to accommodate different diameters of workpieces, and it can also move forward and backward to adjust the distance between the workpiece and the guide sleeve end to adapt to different thicknesses of workpieces.

| Model | SZ25 | SZ40/2 | SZ4585/2 | Unit | |

| Maximum workpiece diameter in one clamping | Φ2500 | Φ2000 | Φ4500 | mm | |

| Maximum machinable diameter by turning 180° | Φ3000 | Φ4000 | Φ8000 | mm | |

| Drill diameter | Gundrill | Φ16—Φ24 | Φ16—Φ24 | Φ16—Φ24 | mm |

| BTA Drilling | Φ16—Φ40 | Φ16—Φ45 | Φ16—Φ80 | mm | |

| Maximum drilling depth | 800 | 800 | 1000 | mm | |

| Spindle speed | 30—3000 | 30—3000 | 30—3000 | r/min | |

| Spindle servo motor power | 2×15/22 | 2×15/22 | 2×41 | kW | |

| Electrical system | Siemens 828Dsl/840Dsl | ||||