GZP series CNC gantry drilling and milling machine

GZP series CNC gantry drilling and milling machine, with gantry moving, table fixed structure form, which is more suitable for heavy-duty cutting of workpieces such as large flanges, slewing ring bearings, and tube sheets. The workpiece can be drilled, milled, bored, reamed and countersunk in one clamping.

The machine is equipped with a standard BT50 internal cooling rigid high-speed precision spindle,and the efficiency is increased by 50%.

It is suitable for machining in wind power, nuclear power, metallurgy, petrochemical, shipbuilding,construction machinery and other fields.

Drilling

Milling

Boring

Tapping

Flange – Wind Power

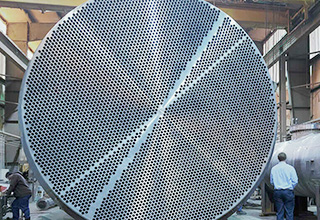

Large Tube Plate

Slewing ring bearing-Wind Power

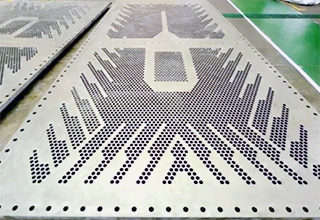

Large Cable Base

Tube Plate – Power Plant

★The flat lay type gantry moving high-speed CNC drilling and milling machine,which can be adapted to the batch processing of tube plates, flanges, bearings and large structural parts. It can be processed using high-speed hard alloy internal cooling tools and also can use high-speed steel tools for external cooling.

★The main body of the equipment adopts a flat-type structure, with the bed and worktable being mutually independent. Both the bed and worktable are fixed on the foundation with the gantry spanning across the bed.

★The drilling and milling spindle uses a BT series rigid and precise main spindle, with high-speed drilling and light milling functions.

★The main spindle is driven by a high-power spindle servo motor, with a maximum torque of up to 1500Nm. It can process a Ø120mm hole in one go using hard alloy cutting tools, and achieve rigid tapping and contour milling.

★The power head adopts the T-shaped guide rail form of a gantry boring and milling machine, which provides excellent rigidity and strong stability.

★The gantry structure adopts a # shaped reinforcement welding structure with gantry milling, possessing exceptional dynamic and static rigidity to ensure the strength and precision stability of the machine tool.

| Model | GZP30 | GZP40 | GZP50 | GZP60 | GZP70 | GZP80 | GZP90 | GZP100 | GZP120 | GZP160 | Unit |

| Processing range | 3000×

3000 |

4000×

4000 |

5000×

5000 |

6000×

6000 |

7000×

7000 |

8000×

8000 |

9000×

9000 |

10000×

10000 |

12000×

12000 |

16000×

16000 |

mm |

| Spindle specifications | BT50 | BT50 | BT50 | BT50 | BT50 | BT50 | BT50 | BT50 | BT50 | BT50 | |

| Maximum drilling diameter | Φ100 | Φ100 | Φ100 | Φ100 | Φ100 | Φ100 | Φ100 | Φ120 | Φ120 | Φ120 | mm |

| Spindle peed | 30—3000 | r/min | |||||||||

| Spindle servo motor power | 37 | 37 | 37 | 45 | 45 | 45 | 45 | 55 | 55 | 55 | kW |

| Maximum spindle orque | 700 | 700 | 700 | 700 | 700 | 700 | 700 | 1200/1500 | 1200/1500 | 1200/1500 | Nm |

| Electrical system | Siemens 828Dsl/840Dsl | ||||||||||