GZC series gantry CNC drilling and milling machine

GZC series gantry CNC drilling and milling machine has a compact overall structure and a small footprint. It can be drilled with hard alloy internal cooling drills or high-speed steel twist drills with external cooling.

GZC series gantry CNC drilling and milling machine, with compact overall structure and small footprint, can be used for drilling with carbide internal cold drill bit or high-speed steel twist drill bit with external cooling.

Drilling

Milling

Tapping

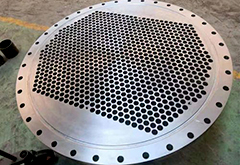

Tube sheet-Heat Exchanger

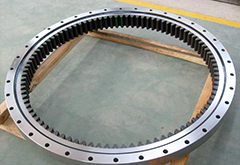

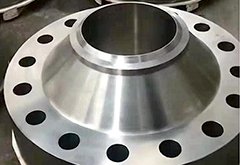

Flange-Wind Power

Slewing ring bearing-Wind Power

Vacuum pump base-Metallurgy

Flange-Mechanical engineering

Baffle-Chemical Heat Exchanger

★GZC series gantry CNC drilling and milling machine ,which can be processed using high-speed hard alloy internal cooling tools and also can use high-speed steel tools for external cooling.

★This equipment is mainly used for processing installation holes for flanges, heat exchangers, tube sheet components, and large slewing bearing inner and outer rings.

★The drilling and milling power head adopts the BT series rigid precision spindle for high-speed drilling and also has a light milling function.

★The main spindle is driven by a high-power spindle servo motor, with a maximum torque of 700Nm. It can process a hole diameter of Φ80mm with a hard alloy tool and can also achieve rigid tapping and contour milling.

★The power head adopts the T-shaped guide rail form of the gantry boring and milling machine, which has good rigidity and strong stability.

★The gantry structure adopts a well-type reinforcement welding structure of gantry milling, which has super strong dynamic and static rigidity, ensuring stable strength and accuracy of the machine tool.

| Model | GZC30 | GZC40 | GZC50 | GZC60 | Unit |

| Processing range | 3000×3000—24000 | 4000×4000—24000 | 5000×5000—24000 | 6000×6000—24000 | mm |

| Spindle specifications | BT50 | BT50 | BT50 | BT50 | |

| Maximum drilling diameter | Φ80 | Φ80 | Φ80 | Φ80 | mm |

| Spindle speed | 30—3000 | 30—3000 | 30—3000 | 30—3000 | r/min |

| Spindle servo motor power | 37 | 37 | 37 | 37 | kW |

| Maximum spindle torque | 700 | 700 | 700 | 700 | Nm |

| ctrical system | Siemens 828Dsl/840Dsl | ||||