CJHZ series gantry CNC drilling and milling machine

CJHZ series gantry CNC drilling and milling machine with compact overall structure and small footprint. It is suitable for the drilling of medium and small workpieces such as connecting plates,End-Plate Connection, flanges, baffles, etc. in steel structures, bridges, iron towers, boilers, petrochemical and other industries.

Drilling

Milling

Tapping

Connecting plate-Steel Structure

Flange-Mechanical Engineering

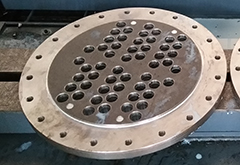

Tube Sheet-Chemical Heat Exchanger

Baffle-Chemical Heat Exchanger

★Gantry moving high-speed CNC drilling and milling machine is a flexible CNC drilling and milling machine,which can be adapted to the mass production of multi-species products,It can use carbide cutters for drilling, tapping and light milling , or drilling with HSS twist drills.

★This equipment is mainly used for drilling, tapping, and milling of plate workpieces in steel structure industries such as construction, bridges, and iron towers. It can also be used for drilling, tapping, and light milling of tube sheets, baffle plates, and circular flanges in the boiler and petrochemical industries.

★This equipment mainly consists of the bed and longitudinal sliding table, gantry and transverse sliding table, pillow type drilling power head, automatic chip conveyor and circulating cooling device, hydraulic system and electrical system, etc.

★The equipment has an independent hydraulic power system and electrical numerical control system with centralized control.

★The drilling power head adopts the BT series internal cooling rigid precision spindle, equipped with a hydraulic cylinder, and the spindle is driven by a high-power spindle motor through a synchronous belt.

★Its CNC axes are guided by linear guide rail pairs, and servo motors drive ball screw pairs.

| Model | CJ1610HZ | CJ1616HZ | CJ2016HZ | CJ2020HZ | CJ3016HZ | CJ3030HZ | Unit |

| Maximum processing range | 1000×1600 | 1600×1600 | 2000×1600 | 2000×2000 | 3000×1600 | 3000×3000 | mm |

| Maximum orkpiece thickness | 150 | 150 | 200 | 200 | 200 | 200 | mm |

| Spindle taper hole | BT40 | BT40 | BT40/BT50 | BT40/BT50 | BT40/BT50 | BT40/BT50 | |

| Maximum drilling diameter | Φ5—Φ40 | Φ5—Φ40 | Φ5—Φ40 | Φ5—Φ40 | Φ5—Φ50 | Φ5—Φ50 | mm |

| Tapping diameter range | M24 | M24 | M24 | M24 | M30 | M30 | mm |

| Maximum milling disc diameter | Φ100 | Φ100 | Φ100 | Φ100 | Φ160 | Φ160 | mm |

| Spindle speed | 30—6000 | 30—6000 | 30—6000 | 30—6000 | 30—6000 | 30—6000 | r/min |

| Spindle servo motor power | 15/18.5 | 15/18.5 | 15/18.5 | 15/18.5 | 22 | 22 | kW |

| Electrical system | Siemens 808Dsl | ||||||