GSWZ series high speed beam drilling line

GSWZ series high speed beam drilling line, scribing and marking functions and consists of three independent spindles, which can drill independently or simultaneously.

It is suitable for drilling and processing of H-beams and channel steel in steel structures and is widely used in steel structures such as buildings, bridges, power stations, three-dimensional garages, offshore oil well platforms and tower masts.

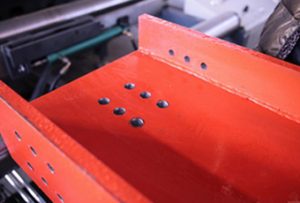

Drilling

Scribing

Marking

H beam-Steel Structure

H beam-Steel Structure

★GSWZ series high speed beam drilling line is a flexible CNC production line , which can adapt to mass production of multi-species profiles and use hard alloy cutting tools or HSS twist drills.

★The production line consists of GSWZ/3A series high speed beam drilling line , upper and lower material conveying channels, CNC feeding device, and transverse material platform. It is equipped with electrical control system, hydraulic system, pneumatic cooling, and lubrication system.

★The machine main unit adopts a steel plate welded gantry structure, which is particularly suitable for high-speed, medium and small-sized steel processing.

★The drilling power head adopts the BT series rigid precision main spindle, which is driven by a high-power spindle motor. The feed is driven by a servo motor through a ball screw pair, with accurate positioning, and can automatically complete the transition between rapid feed, working feed, and rapid retreat.

★The main unit can be equipped with a tool magazine to adapt to the processing of holes of various specifications.

★This production line can be combined with our sawing machine and locking production line to form a flexible production line for secondary CNC steel processing equipment.

| Model | GSWZ400/3A | GSWZ700/3A | GSWZ1000/3A | GSWZ1250/3A | Unit |

| Maximum workpiece | 400×400 | 700×400 | 1000×500 | 1250×600 | mm |

| Minimum workpiece | 150×40

(Channel steel) |

150×40

(Channel steel) |

150×40

(Channel steel) |

150×40

(Channel steel) |

mm |

| 150×80

(H-beam) |

150×80

(H-beam) |

150×80

(H-beam) |

150×80

(H-beam) |

||

| Spindle taper hole | BT40 | BT40 | BT40 | BT40 | |

| Maximum drilling diameter | Φ5—Φ40 | Φ5—Φ40 | Φ5—Φ40 | Φ5—Φ40 | mm |

| Spindle speed | 30—3000 | 30—3000 | 30—3000 | 30—3000 | r/min |

| Spindle servo motor power | 3×15 | 3×15 | 3×15 | 3×15 | kW |

| Electrical system | PLC/Siemens 840Dsl | ||||